Origins in the Lab

Pullulan's discovery dates back to the early 20th century, when scientists first isolated and characterized this fascinating polysaccharide. Early research centered on understanding its chemical structure and biological functions, laying the groundwork for its eventual commercialization. As scientists delved deeper into pullulan's properties, they uncovered its potential to revolutionize various industries through its versatility and sustainability.

Chemical Structure

Pullulan is a linear polysaccharide composed of maltotriose units linked by α-1,6-glucosidic bonds. This unique structure imparts pullulan with exceptional physical and chemical properties such as high viscosity, excellent film-forming ability, plasticity, and biocompatibility.

Biological Functions

Biocompatibility: Pullulan is non-toxic, non-allergenic, and biodegradable, making it ideal for applications in the pharmaceutical industry, including drug carriers and wound dressings.

Film-forming Ability: Pullulan's remarkable film-forming capability enables it to create transparent, strong, oil-resistant, and heat-sealable films widely used in food and medical packaging.

Plasticity: Pullulan's plasticity allows it to be molded into various shapes, catering to the needs of diverse industries.

Potential Applications Across Industries

Food Industry

Thickener: Pullulan acts as a thickener in food products, enhancing their texture and mouthfeel.

Preservative: Its film-forming property makes pullulan an effective food preservative, extending product shelf life.

Pharmaceutical Sector

Drug Carrier: Pullulan's biocompatibility and biodegradability render it a superior drug carrier for controlled drug release and enhanced therapeutic efficacy.

Wound Dressing: Its moisture-absorbing and breathable nature make pullulan an ideal material for wound dressings, facilitating faster healing.

Environmental Protection

Heavy Metal Ion Removal: Pullulan exhibits excellent adsorption capabilities for heavy metal ions, making it useful in wastewater treatment.

Bioflocculant: As a bioflocculant, pullulan shows promise in environmental management, such as treating oily wastewater and dyeing effluents.

Other Fields

Cosmetics: Pullulan finds applications in cosmetics as a stabilizer and thickener.

Petroleum Industry: In the petroleum sector, pullulan serves as an oil displacement agent and water-plugging agent.

Data and Examples

Fermentation Yield: Optimized fermentation conditions can yield high pullulan production rates, with some high-yielding strains achieving polysaccharide yields of 60-70g/L and sugar conversion rates of 60%-70% after 96 hours of fermentation.

Film Properties: Pullulan films at a mass concentration of 5% exhibit exceptional gas barrier properties, allowing minimal passage of gases like oxygen, nitrogen, and carbon dioxide but permitting significant moisture permeability.

Application Examples: In food packaging, pullulan films are prized for their transparency, strength, oil resistance, and heat-sealability. In the pharmaceutical sector, pullulan-based products such as drug carriers and wound dressings are already in use.

In summary, pullulan, as a multifunctional biopolymer, holds immense potential for commercialization across food, medicine, environmental protection, and other industries. As research progresses, its applications are expected to expand even further.

Food Industry Applications

One of the first and most prominent applications of pullulan has been in the food industry. As a natural thickening and stabilizing agent, pullulan enhances the texture and shelf life of various food products. It is commonly used as a fat replacer in low-calorie and reduced-fat foods, allowing manufacturers to create healthier alternatives without compromising on taste or texture. Furthermore, pullulan's film-forming properties make it an ideal coating for confectionery, where it prevents moisture loss and enhances product appearance.

Let's delve deeper into the significant role of pullulan in the food industry, highlighting its use as a natural thickening and stabilizing agent, fat replacer, and coating material, accompanied by data and examples.

Thickening and Stabilizing Agent

Pullulan's unique physicochemical properties, including its high viscosity and stability over a wide pH range, make it an excellent thickening and stabilizing agent in the food industry. It enhances the texture of food products, providing a creamy, smooth, and mouth-coating sensation.

Data and Examples:

Viscosity: Pullulan exhibits a high viscosity even at low concentrations, allowing manufacturers to use it effectively in small amounts. For instance, a 1% pullulan solution can achieve a viscosity similar to that of a 10% starch solution.

Shelf Life Extension: By forming a protective barrier around food particles, pullulan helps to retain moisture and prevent oxidation, thereby extending the shelf life of products. Studies have shown that pullulan-coated foods can maintain their quality for longer periods compared to uncoated counterparts.

Fat Replacer

In response to the growing demand for healthier food options, pullulan has emerged as a versatile fat replacer in low-calorie and reduced-fat foods. Its ability to mimic the texture and mouthfeel of fat makes it an attractive alternative for manufacturers looking to reduce fat content without compromising on taste.

Data and Examples:

Calorie Reduction: Pullulan is virtually calorie-free, allowing food manufacturers to replace up to 50% of the fat content in products like creamers, spreads, and dressings, significantly reducing their caloric value.

Texture Mimicry: Research has demonstrated that pullulan can effectively replicate the creamy texture of fat-containing foods, making it a suitable replacement in dairy-based products like yogurt and ice cream. For example, pullulan-based ice cream formulations have been shown to maintain a smooth and creamy texture similar to full-fat ice cream.

Film-Forming Properties for Confectionery Coating

Pullulan's film-forming properties are particularly valuable in the confectionery industry, where it is used as a coating for candies, chocolates, and other sweet treats. The resulting film is transparent, glossy, and resistant to moisture loss, enhancing the product's appearance and extending its shelf life.

Data and Examples:

Moisture Resistance: Pullulan films have been shown to effectively prevent moisture loss from coated candies, even under humid conditions. This helps to maintain the product's freshness and prevent sticking or clumping.

Appearance Enhancement: The transparent and glossy film formed by pullulan enhances the visual appeal of confectionery products, making them more attractive to consumers. For instance, pullulan-coated chocolates exhibit a shiny, smooth surface that catches the eye and elevates the overall presentation.

Pullulan's versatility as a natural thickening and stabilizing agent, fat replacer, and coating material in the food industry underscores its importance and potential for commercialization. Its ability to enhance product texture, shelf life, and appearance, while also contributing to healthier food options, makes it a valuable addition to the food industry's toolbox.

Pharmaceutical and Medical Uses

The pharmaceutical industry has also embraced pullulan due to its biocompatibility and non-toxic nature. Pullulan-based tablets have excellent disintegration properties, ensuring rapid drug release and improved bioavailability. Additionally, pullulan is used as a carrier for controlled drug delivery systems, enabling sustained or targeted release of therapeutic agents. In the field of medical devices, pullulan-based coatings have been developed to improve biocompatibility and reduce the risk of infection.

The pharmaceutical industry's adoption of pullulan stems from its unique combination of biocompatibility, non-toxicity, and functional properties, which make it a valuable material for drug formulation, controlled drug delivery, and medical device coatings. Let's explore these applications in detail, supported by data and examples.

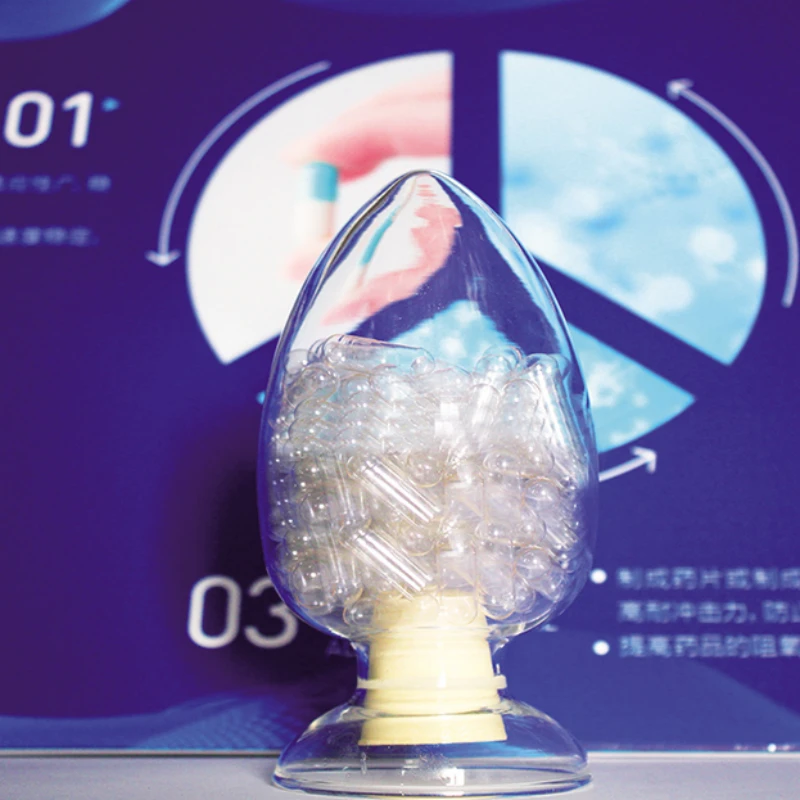

Pullulan-Based Tablets for Drug Delivery

Pullulan-based tablets exhibit exceptional disintegration properties, facilitating rapid drug release and enhanced bioavailability. This is particularly important for drugs that require fast onset of action or have limited solubility in the gastrointestinal tract.

Data and Examples:

Disintegration Time: Studies have shown that pullulan-based tablets disintegrate significantly faster than those made with traditional excipients like starch or lactose. For instance, pullulan tablets can disintegrate within minutes after administration, ensuring prompt drug release.

Bioavailability: The rapid disintegration of pullulan-based tablets often leads to improved bioavailability of the encapsulated drug, as more of the active ingredient is released and absorbed into the bloodstream. This can translate into more effective treatments and potentially lower doses required.

Pullulan as a Carrier for Controlled Drug Delivery Systems

Pullulan's versatility extends to its use as a carrier in controlled drug delivery systems, enabling sustained or targeted release of therapeutic agents. This allows for more precise dosing and improved patient outcomes.

Data and Examples:

Sustained Release: Pullulan can be modified to form matrices or microspheres that slowly release drugs over an extended period. This is useful for treating chronic conditions, where continuous, low-dose therapy is desired. For example, pullulan-based microspheres have been developed to deliver antibiotics, hormones, and other drugs in a sustained manner.

Targeted Delivery: By incorporating targeting ligands onto pullulan-based carriers, it is possible to direct drugs specifically to diseased cells or tissues. This minimizes side effects and enhances therapeutic efficacy. Research has demonstrated the successful use of pullulan-based nanoparticles for targeted delivery of anticancer drugs to tumor cells.

Pullulan-Based Coatings for Medical Devices

In the field of medical devices, pullulan-based coatings have been developed to improve biocompatibility and reduce the risk of infection. Pullulan's natural affinity for water and ability to form a smooth, non-adhesive surface make it an ideal material for coating implants, stents, and other medical devices.

Data and Examples:

Biocompatibility: Pullulan coatings have been shown to be non-irritating and non-toxic to cells and tissues, making them safe for use in medical devices. Studies have demonstrated the excellent biocompatibility of pullulan-coated implants, with minimal inflammation or rejection by the host body.

Infection Prevention: The hydrophilic nature of pullulan coatings promotes the formation of a hydration layer that inhibits bacterial adhesion and biofilm formation. This helps to reduce the risk of infection associated with medical devices. For instance, pullulan-coated stents have been shown to exhibit reduced rates of infection and inflammation compared to uncoated stents.

In summary, pullulan's biocompatibility, non-toxicity, and functional properties make it a valuable material for the pharmaceutical industry. Its use in pullulan-based tablets, controlled drug delivery systems, and medical device coatings has the potential to improve drug efficacy, patient outcomes, and overall patient safety.

Industrial and Packaging Solutions

Pullulan's biodegradability and film-forming abilities have made it an attractive material for sustainable packaging solutions. Pullulan films are transparent, flexible, and have excellent barrier properties against oxygen and moisture, making them ideal for extending the shelf life of perishable goods. Moreover, pullulan-based packaging materials can be easily composted, reducing waste and environmental impact.

Pullulan's biodegradability and film-forming abilities have indeed made it a highly attractive material for sustainable packaging solutions. The following details illustrate its advantages in this context, supported by relevant data and examples.

Biodegradability

Pullulan is a natural polysaccharide produced by fermentation, making it inherently biodegradable. This characteristic sets it apart from traditional non-biodegradable packaging materials like plastics, which can persist in the environment for centuries.

Data and Examples:

Biodegradation Time: While exact biodegradation times can vary depending on environmental conditions, pullulan films are known to decompose rapidly in composting environments. Studies have shown that pullulan-based packaging materials can be fully biodegraded within a relatively short period, significantly reducing waste accumulation and the need for long-term disposal solutions.

Film-Forming Abilities

Pullulan possesses excellent film-forming abilities, allowing it to be processed into thin, transparent, and flexible films that are suitable for a wide range of packaging applications.

Data and Examples:

Transparency: Pullulan films exhibit high transparency, which is crucial for packaging applications where visual inspection of the packaged goods is important. This transparency allows consumers to easily identify the product's quality and freshness.

Flexibility: The flexibility of pullulan films enables them to conform to the shape of the packaged goods, providing a snug and protective fit. This also allows for easier handling and processing during the packaging process.

Barrier Properties

Pullulan films possess excellent barrier properties against oxygen and moisture, which are two major factors that can lead to the spoilage of perishable goods.

Data and Examples:

Oxygen Barrier: Pullulan films have been shown to effectively inhibit the permeation of oxygen, which can slow down oxidative reactions that lead to the degradation of packaged foods. This extended shelf life by preserving the freshness and nutritional value of the goods.

Moisture Barrier: Similarly, pullulan films provide an effective barrier against moisture, preventing the ingress of water vapor that can cause moisture-induced spoilage. This is particularly important for packaging hygroscopic products like dried fruits, vegetables, and cereals.

Environmental Impact

The use of pullulan-based packaging materials can significantly reduce waste and environmental impact.

Data and Examples:

Compostability: As mentioned earlier, pullulan films are easily compostable, allowing them to be safely disposed of in composting facilities. This not only reduces the volume of waste sent to landfills but also promotes the circular economy by converting waste into valuable compost.

Reduced Carbon Footprint: The production of pullulan-based packaging materials typically involves fewer harmful emissions and consumes less energy compared to the production of traditional plastics. This helps to reduce the overall carbon footprint of the packaging industry.

Pullulan's biodegradability, film-forming abilities, and excellent barrier properties make it an ideal material for sustainable packaging solutions. Its use in packaging applications has the potential to significantly reduce waste, minimize environmental impact, and extend the shelf life of perishable goods.

Cosmetics and Personal Care

The cosmetics industry has also tapped into pullulan's potential, utilizing its ability to form smooth and non-sticky films. Pullulan is often used as a texturizer and stabilizer in skincare products, enhancing their feel and ensuring consistent performance. Additionally, its film-forming properties make pullulan an effective ingredient in hair care products, providing a smooth and silky finish.

The cosmetics industry has indeed recognized the multifaceted potential of pullulan, harnessing its unique properties to enhance the quality and performance of skincare and hair care products. The following details illustrate how pullulan is utilized in these applications, supported by relevant data and examples.

Skincare Products

In skincare, pullulan is highly valued for its ability to form smooth and non-sticky films, making it an ideal texturizer and stabilizer.

Texturizer: Pullulan's film-forming properties allow it to improve the texture of skincare products, giving them a silky, smooth feel upon application. This enhances the overall sensory experience for the user, making the product more pleasant to use.

Stabilizer: Pullulan also acts as a stabilizer, helping to maintain the product's consistency and preventing the separation of ingredients over time. This ensures that the product remains effective and performs consistently, even after prolonged storage.

Data and Examples:

Product Enhancement: Manufacturers often incorporate pullulan into creams, lotions, and serums to give them a luxurious, lightweight texture that absorbs quickly into the skin. This not only improves the product's appearance but also enhances its efficacy by allowing the active ingredients to penetrate deeper into the skin.

Consumer Preferences: Market research has shown that consumers increasingly prefer skincare products that are lightweight, non-greasy, and easy to absorb. Pullulan's texturizing properties make it a valuable ingredient in meeting these preferences.

Hair Care Products

In hair care, pullulan's film-forming abilities make it an effective ingredient for providing a smooth and silky finish.

Smoothing Agent: Pullulan forms a thin, invisible film around the hair strands, helping to smooth out frizz and reduce flyaways. This gives the hair a polished, sleek look that is easy to manage and style.

Conditioning Effect: The film also acts as a conditioning agent, helping to retain moisture and protect the hair from damage caused by heat styling and environmental factors. This promotes healthier, more manageable hair.

Data and Examples:

Product Formulations: Hair care products such as hair serums, conditioners, and styling creams often contain pullulan to improve their performance. These products are designed to provide a smooth, silky finish while also nourishing and protecting the hair.

Consumer Reviews: Consumer reviews of hair care products containing pullulan often mention the improved smoothness and manageability of their hair, as well as the long-lasting conditioning effects.

In summary, pullulan's unique properties make it a valuable ingredient in both skincare and hair care products. Its ability to form smooth and non-sticky films enhances the texture and feel of these products, while also providing additional benefits such as stabilization and conditioning. The incorporation of pullulan into cosmetics formulations is a testament to its versatility and effectiveness in meeting the evolving needs of consumers.

Agriculture and Biotechnology

More recently, pullulan has found applications in agriculture and biotechnology. Its biodegradability and non-toxicity make it a suitable material for agricultural films and coatings, which can improve crop yields and reduce the use of harmful chemicals. In biotechnology, pullulan is being explored as a carrier for enzymes and other bioactive molecules, enabling their targeted delivery and enhanced activity.

Pullulan, with its biodegradability and non-toxicity, has recently garnered significant attention in the fields of agriculture and biotechnology. Its unique properties make it an ideal material for various applications that aim to improve crop yields, reduce environmental impact, and enhance the efficacy of bioactive molecules.

Agriculture

In agriculture, pullulan's biodegradability and environmental friendliness have made it a suitable material for agricultural films and coatings.

Agricultural Films:

Biodegradable Films: Pullulan-based films can be used as alternatives to traditional, non-biodegradable plastic films used in agriculture. These films can be used for mulching, greenhouses, and seedling trays, among other applications.

Crop Yield Improvement: By regulating soil temperature, moisture, and inhibiting weed growth, pullulan-based films have been shown to improve crop yields. Studies have reported increases in yield ranging from a few percent to as much as 20-30%, depending on the crop and specific conditions.

Reduced Chemical Use: The use of pullulan-based films can also help reduce the need for harmful pesticides and herbicides, making agriculture more sustainable.

Examples and Data:

Mulching Films: Pullulan-based films have been tested in various crops, such as tomatoes, peppers, and cucumbers, with positive results in terms of yield and fruit quality.

Environmental Impact: A study comparing pullulan-based films with conventional plastics found that the former degraded more quickly and completely in soil, reducing long-term environmental pollution.

Biotechnology

In biotechnology, pullulan's ability to form stable and non-toxic films has made it a promising carrier for enzymes and other bioactive molecules.

Carrier for Enzymes and Bioactive Molecules:

Targeted Delivery: Pullulan can encapsulate enzymes, drugs, and other bioactive molecules, enabling their targeted delivery to specific sites within the body or plants. This enhances their activity and reduces the required dosage.

Controlled Release: The films formed by pullulan can also be designed to release the encapsulated molecules in a controlled manner, allowing for sustained activity over an extended period.

Examples and Data:

Enzyme Delivery: Pullulan-based encapsulation of enzymes has been explored for applications in biofuels production, where enzymes are used to break down lignocellulosic biomass. The pullulan films protected the enzymes from degradation and allowed for controlled release, resulting in improved biofuel yields.

Drug Delivery: In the pharmaceutical industry, pullulan-based nanoparticles are being investigated as carriers for anticancer drugs, with the potential to improve drug efficacy and reduce side effects.

In conclusion, pullulan's biodegradability, non-toxicity, and film-forming abilities have made it a valuable material for applications in agriculture and biotechnology. Its use in agricultural films and coatings can improve crop yields and reduce chemical usage, while its potential as a carrier for enzymes and bioactive molecules in biotechnology holds great promise for targeted delivery and enhanced activity.

Conclusion

From its humble beginnings in scientific laboratories, pullulan has emerged as a versatile and sustainable material with a wide range of commercial applications. Its unique properties have made it an invaluable addition to the food, pharmaceutical, industrial, cosmetics, agriculture, and biotechnology industries. As research continues to uncover new uses for pullulan, its commercial potential will continue to grow, driving innovation and sustainability in various sectors.