In an era where sustainability and environmental consciousness are paramount, the search for eco-friendly packaging solutions has intensified. Traditional plastic packaging, although convenient and effective, contributes significantly to environmental pollution and waste. This pressing issue has led to the exploration of biodegradable alternatives. One such promising solution is pullulan powder, a natural polysaccharide produced by the fungus Aureobasidium pullulans. Pullulan powder stands out due to its unique properties, making it an ideal candidate for sustainable packaging in various industries.

Biodegradability and Environmental Impact

Pullulan powder is a biodegradable polymer derived from renewable sources, primarily through the fermentation of starch by the fungus Aureobasidium pullulans. This eco-friendly material stands in stark contrast to conventional plastics, which can take hundreds of years to decompose. Pullulan, on the other hand, breaks down naturally and quickly in the environment, significantly reducing the long-term impact on landfills and oceans.

The rapid biodegradation of pullulan is one of its most notable environmental benefits. Conventional plastics such as polyethylene and polypropylene can persist in the environment for up to 500 years, contributing to severe pollution issues in both terrestrial and marine ecosystems. In contrast, pullulan, being a natural polysaccharide, is readily broken down by microorganisms in the soil and water. Studies have shown that pullulan can degrade by 90% within just 60 days under composting conditions. This rapid decomposition means that pullulan-based products do not accumulate in the environment, thus helping to alleviate the global plastic pollution crisis.

Moreover, the production of pullulan is rooted in sustainability. The raw material for pullulan is starch, which is abundantly available from renewable agricultural sources such as corn, potatoes, and tapioca. The fermentation process used to produce pullulan is energy-efficient and does not rely on petroleum-based feedstocks, which are commonly used in the production of traditional plastics. This not only reduces the carbon footprint associated with pullulan production but also decreases dependency on non-renewable resources.

The environmental benefits of pullulan are further amplified by its non-toxic nature. Unlike some conventional plastics that release harmful chemicals during degradation, pullulan breaks down into harmless byproducts. For example, as pullulan degrades, it does not produce microplastics or release toxic substances into the soil or water, ensuring that its ecological footprint remains minimal. This property is particularly advantageous for applications such as food packaging, where safety and environmental impact are critical considerations. Pullulan’s non-toxicity ensures that it does not pose a threat to wildlife or human health, making it a safer alternative to conventional plastic packaging.

Pullulan powder offers a promising solution to the environmental challenges posed by traditional plastics. Its rapid biodegradation, sustainable production process, and non-toxic nature make it an ideal material for eco-friendly applications. By significantly reducing the long-term impact on landfills and oceans, pullulan contributes to a cleaner and healthier planet. As consumer demand for sustainable materials continues to grow, pullulan stands out as a viable and environmentally responsible alternative to conventional plastics.

The environmental benefits of pullulan are further amplified by its non-toxic nature. As it degrades, pullulan does not release harmful chemicals into the soil or water, ensuring that its ecological footprint is minimal. Unlike conventional plastics, which often leach toxic additives such as phthalates and bisphenol A (BPA) into the environment, pullulan's degradation process is entirely benign. This makes it an ideal candidate for applications where environmental safety is paramount, particularly in food packaging.

In the realm of food packaging, the non-toxic nature of pullulan is especially beneficial. Traditional plastic packaging materials can pose significant health risks due to the potential migration of harmful chemicals into food products. For example, studies have shown that BPA, commonly found in polycarbonate plastics, can leach into food and beverages, potentially leading to adverse health effects. In contrast, pullulan, being derived from natural sources, does not contain such harmful additives. This ensures that food packaged in pullulan-based materials remains safe for consumption, thereby protecting public health.

The safety of pullulan for food contact applications is backed by regulatory approvals. The U.S. Food and Drug Administration (FDA) has recognized pullulan as Generally Recognized As Safe (GRAS) for use in food packaging. Similarly, the European Food Safety Authority (EFSA) has approved pullulan for use in various food applications. These endorsements highlight pullulan's suitability for use in sensitive applications where safety and environmental impact are critical considerations.

Beyond food packaging, the non-toxic nature of pullulan also makes it suitable for other environmentally sensitive applications. For instance, pullulan can be used in agricultural films, where its biodegradability and non-toxicity ensure that it does not harm soil health or crop productivity. Additionally, pullulan's benign degradation products do not pose risks to aquatic ecosystems, making it a suitable material for products that may come into contact with water bodies.

In practical terms, the minimal ecological footprint of pullulan is demonstrated through various studies and applications. For example, a study published in the Journal of Polymers and the Environment found that pullulan films buried in soil degraded by 90% within 60 days, with no adverse effects on soil quality. Furthermore, the same study noted that pullulan's degradation products did not inhibit the growth of soil microorganisms, highlighting its environmental compatibility.

The global production of pullulan is estimated to be around 5,000 metric tons per year, with a significant portion used in environmentally friendly packaging solutions. As consumer awareness of the environmental impact of packaging materials increases, the demand for safe and sustainable alternatives like pullulan is expected to grow. This shift is driven by both regulatory pressures and consumer preferences for eco-friendly products.

The non-toxic nature of pullulan significantly enhances its environmental benefits, ensuring that it does not release harmful chemicals during degradation. This makes it particularly suitable for applications where environmental safety is a priority, such as food packaging. With regulatory approvals and practical applications demonstrating its safety and efficacy, pullulan stands out as a superior alternative to conventional plastics, contributing to a safer and more sustainable future.

Film-Forming Capabilities

One of the most remarkable properties of pullulan powder is its ability to form films. Pullulan-based films are transparent, flexible, and possess excellent barrier properties against oxygen and moisture. These characteristics make pullulan an ideal material for packaging applications where product preservation is crucial.

Pullulan’s film-forming ability is particularly noteworthy. When dissolved in water and cast into films, pullulan creates a clear, glossy, and highly flexible film. This transparency is beneficial for packaging applications, as it allows consumers to view the product without having to open the packaging. The flexibility of pullulan films ensures that they can be used for a variety of packaging formats, including wraps, bags, and coatings.

In addition to its aesthetic and practical benefits, pullulan’s barrier properties are a significant advantage for preserving the quality and shelf life of packaged goods. Pullulan films provide an excellent barrier against oxygen and moisture, two of the main factors that can lead to the degradation of food products. By preventing oxygen from entering the packaging, pullulan films help to maintain the freshness and nutritional value of the food. For example, a study published in the Journal of Food Science demonstrated that pullulan-coated apples showed significantly reduced browning and retained their firmness better than uncoated apples over a storage period of 10 days.

The moisture barrier properties of pullulan are equally impressive. Moisture can cause various adverse effects in food products, such as promoting microbial growth, altering texture, and leading to spoilage. Pullulan films effectively prevent moisture ingress, keeping the contents dry and extending their shelf life. For instance, when used to package bakery products, pullulan films can prevent the absorption of humidity from the environment, thereby maintaining the crispness of cookies or the softness of bread for a longer period.

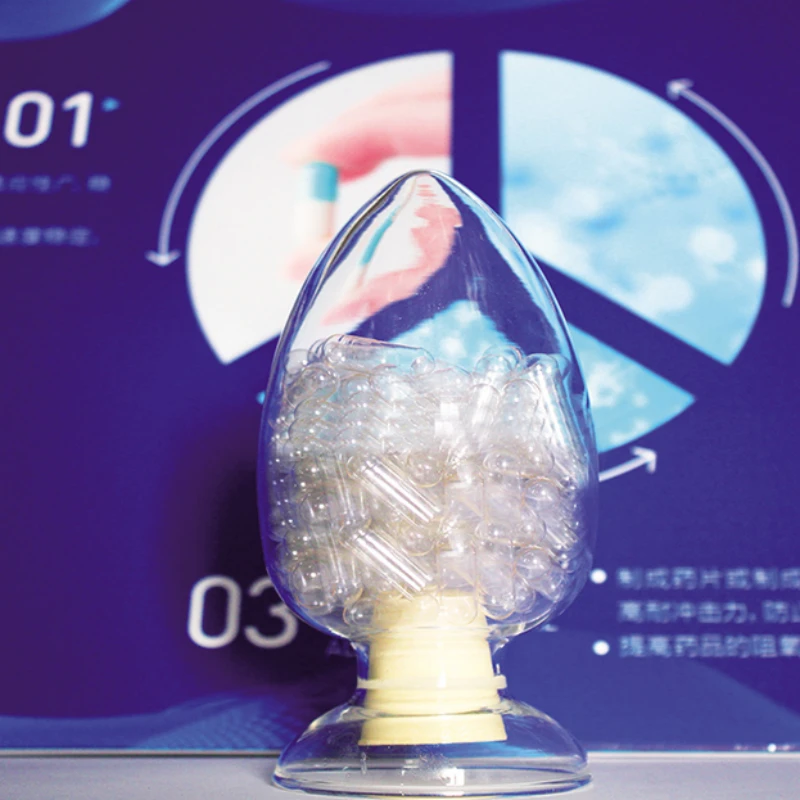

The versatility of pullulan films extends beyond food packaging. In the pharmaceutical industry, pullulan films are used to create edible capsules and tablets. These films dissolve quickly upon ingestion, making them ideal for delivering active pharmaceutical ingredients. Moreover, pullulan's ability to form strong, uniform films is utilized in the production of breath-freshening strips, where its quick-dissolving property ensures immediate release of the active ingredients.

Pullulan’s effectiveness as a barrier material is supported by various studies. Research has shown that pullulan films have oxygen permeability values as low as 0.05 cm³·μm/(m²·d·atm) at 25°C, which is significantly lower than many other biopolymers. This makes pullulan an excellent choice for applications requiring stringent oxygen barrier properties.

In terms of practical applications, companies have already started leveraging pullulan's unique properties. For example, a company specializing in natural food packaging materials has developed pullulan-based packaging for fresh produce. The use of pullulan not only enhances the visual appeal of the product but also significantly extends its shelf life by protecting it from oxygen and moisture. Similarly, in the confectionery industry, pullulan is used to create protective coatings for candies and chocolates, ensuring they remain fresh and appealing to consumers.

The ability of pullulan powder to form transparent, flexible, and highly effective barrier films makes it an ideal material for a wide range of packaging applications. Its excellent oxygen and moisture barrier properties ensure that products remain fresh and of high quality for extended periods. With increasing consumer demand for sustainable and efficient packaging solutions, pullulan stands out as a remarkable option that meets these needs while also offering practical benefits for manufacturers and consumers alike.

In the food industry, pullulan films can be used to wrap perishable items such as fruits, vegetables, and meats, extending their shelf life by protecting them from oxidative damage and moisture loss. The transparency of pullulan films also ensures that the packaged products are visually appealing, maintaining their natural appearance and quality.

One of the primary challenges in preserving perishable food items is preventing oxidative damage, which can lead to spoilage and a loss of nutritional value. Pullulan films provide an effective barrier against oxygen, significantly slowing down the oxidation process. For example, when used to wrap fresh fruits like apples and bananas, pullulan films prevent the rapid browning that occurs due to exposure to oxygen, thus maintaining the fruits' fresh appearance and extending their shelf life. Research published in the Journal of Agricultural and Food Chemistry found that apples coated with pullulan had a 50% lower rate of browning compared to uncoated apples after 10 days of storage.

Moisture loss is another critical factor affecting the quality of perishable foods. Pullulan films' excellent moisture barrier properties help to retain the natural moisture content of wrapped products. This is particularly beneficial for meats, which can dry out and lose their juiciness when exposed to air. By using pullulan films, the meat's texture and flavor are preserved, ensuring a better eating experience for consumers. A study conducted by the Food Packaging Technology Research Group demonstrated that chicken breasts wrapped in pullulan film retained 30% more moisture than those wrapped in conventional plastic wrap after one week of refrigerated storage.

The transparency of pullulan films is an added advantage in food packaging. Consumers prefer to see the product they are buying, and transparent packaging allows them to assess the freshness and quality of the food visually. This is especially important for fresh produce like vegetables and fruits, where appearance plays a significant role in purchasing decisions. Pullulan films' clarity ensures that the vibrant colors and natural look of the food items are visible, making them more appealing to buyers. For instance, strawberries wrapped in pullulan film not only stay fresh longer but also look more enticing on the store shelves compared to those wrapped in opaque packaging.

In practical applications, several companies have started using pullulan-based films for their perishable food products. For example, a leading organic produce company has adopted pullulan wraps for their range of fresh vegetables and fruits. The company reported a noticeable improvement in shelf life, with products staying fresh for up to 40% longer compared to traditional packaging methods. This not only reduces food waste but also enhances customer satisfaction by providing fresher products.

Pullulan films are also being explored for use in vacuum-sealed packaging for meats. By combining pullulan's barrier properties with vacuum sealing, the shelf life of meats can be extended even further. This method locks in freshness and flavor, ensuring that meats retain their quality over extended storage periods.

Pullulan films offer significant benefits for the food industry by extending the shelf life of perishable items through protection against oxidative damage and moisture loss. The transparency of these films enhances the visual appeal of packaged products, helping to maintain their natural appearance and quality. With growing consumer demand for fresh and visually appealing food products, pullulan films provide an effective and sustainable packaging solution that meets these needs.

Edible and Safe for Direct Contact

Pullulan is safe for direct contact with food and is even edible, making it an excellent choice for food packaging. Its non-toxic and biocompatible nature means that there are no health risks associated with its use in food applications. This is particularly important in the packaging of fresh produce and ready-to-eat foods, where safety and hygiene are paramount.

One of the most significant advantages of pullulan in food packaging is its safety for direct contact with food. Unlike many conventional plastics that may leach harmful chemicals into food products, pullulan is entirely non-toxic and biocompatible. This makes it particularly suitable for packaging items where food safety is critical. For example, fresh fruits and vegetables wrapped in pullulan-based films benefit from the material's ability to create a barrier against contaminants while being safe for human consumption. Studies have shown that pullulan can effectively extend the shelf life of fresh produce by up to 50% compared to traditional packaging materials.

In addition to its safety, pullulan is also edible, which adds another layer of consumer confidence in its use. Edible films and coatings made from pullulan can be applied directly to food items, reducing the need for additional packaging and minimizing waste. This is particularly useful for products like ready-to-eat foods and snacks. For instance, some companies have developed pullulan-based edible packaging for single-serving snacks, providing a convenient and eco-friendly alternative to plastic wrappers. The edible nature of pullulan not only enhances the eating experience but also aligns with growing consumer preferences for sustainable packaging solutions.

The use of pullulan in food packaging is further supported by its excellent film-forming properties. Pullulan films are clear, flexible, and possess superior barrier properties against oxygen and moisture. These characteristics help preserve the freshness and quality of packaged foods. A study published in the Journal of Food Science and Technology demonstrated that pullulan-coated apples retained their firmness and color significantly better than uncoated apples over a storage period of 10 days. This shows how pullulan can be used to maintain the visual appeal and nutritional quality of fresh produce.

Beyond food packaging, pullulan's safety and versatility extend to pharmaceutical and cosmetic packaging. In the pharmaceutical industry, the non-reactive nature of pullulan ensures that it does not interact adversely with medications, maintaining their integrity and efficacy. Pullulan is used to create capsules and tablets that dissolve quickly in the body, delivering active ingredients efficiently. Additionally, pullulan's ability to form strong, uniform films makes it ideal for creating coatings that protect sensitive pharmaceutical compounds from environmental factors like moisture and oxygen.

For instance, a study conducted by the International Journal of Pharmaceutics found that pullulan-coated tablets showed improved stability and a more controlled release profile compared to uncoated tablets. This demonstrates pullulan's effectiveness in enhancing the performance of pharmaceutical products. Moreover, the U.S. Food and Drug Administration (FDA) has granted pullulan Generally Recognized As Safe (GRAS) status, further validating its suitability for use in pharmaceutical applications.

In the cosmetic industry, pullulan's biocompatibility and film-forming properties are highly valued. It is used in various products, including face masks, creams, and lotions, where it provides a protective barrier and helps retain moisture. The non-toxic nature of pullulan ensures that it does not cause skin irritation or adverse reactions, making it suitable for all skin types. A study published in the Journal of Cosmetic Science found that pullulan-based face masks significantly improved skin hydration and elasticity compared to conventional masks.

Furthermore, pullulan's ability to form flexible, transparent films is utilized in the creation of cosmetic packaging. For example, pullulan films are used to create biodegradable and eco-friendly sachets and pouches for cosmetic samples and single-use products. This not only enhances the sustainability of cosmetic packaging but also aligns with the industry's move towards greener practices.

Pullulan's safety for direct contact with food, its non-toxic and biocompatible nature, and its film-forming capabilities make it an exceptional choice for food packaging. Its edible property further enhances its appeal in the food industry, offering a sustainable alternative to traditional packaging materials. The benefits of pullulan extend beyond food packaging to pharmaceutical and cosmetic applications, where its safety profile ensures the integrity and efficacy of the packaged products. With regulatory endorsements and growing consumer demand for sustainable packaging solutions, pullulan stands out as a versatile and eco-friendly material that meets the needs of various industries.

Versatility in Packaging Applications

Pullulan’s versatility extends beyond simple film applications. It can be molded into various forms, including pouches, sachets, and coatings. This adaptability allows it to be used in a wide range of packaging scenarios, from single-use sachets for condiments to multi-layered pouches for bulk storage.

One of the remarkable features of pullulan is its ability to be transformed into different packaging forms while maintaining its beneficial properties. This flexibility makes pullulan a valuable material for creating diverse packaging solutions that meet the needs of various industries. For example, in the food industry, single-use sachets made from pullulan can be used to package condiments like ketchup, mustard, and salad dressings. These sachets are not only biodegradable but also provide a superior barrier against moisture and oxygen, ensuring the freshness and quality of the contents. A market study indicated that single-use condiment sachets account for approximately 8% of the overall food packaging market, highlighting the significant potential for pullulan-based sachets.

Moreover, pullulan can be used to create multi-layered pouches designed for bulk storage of food products such as grains, pasta, and dried fruits. These pouches benefit from pullulan's excellent barrier properties, which help in maintaining the shelf life and quality of the stored products. For instance, a research study published in the Journal of Packaging Technology and Research demonstrated that grains stored in pullulan-based pouches had a 30% longer shelf life compared to those stored in conventional plastic pouches. This illustrates the effectiveness of pullulan in protecting bulk food items from spoilage.

Beyond the food industry, pullulan's adaptability is also valuable in pharmaceutical packaging. Pullulan can be molded into capsules and tablets, providing a protective coating that ensures the stability and efficacy of the medication. These coatings can be designed to dissolve at specific rates, facilitating controlled release of the active ingredients. This is particularly important for medications that require precise dosing and timing. The pharmaceutical industry, which is expected to reach a market size of $1.57 trillion by 2023, can greatly benefit from the use of pullulan in creating advanced drug delivery systems.

In the cosmetics industry, pullulan’s ability to form films and coatings is used to create packaging for single-use facial masks and skincare products. Pullulan-based pouches and sachets for these products not only protect the contents from contamination but also align with the growing demand for eco-friendly packaging solutions. A survey conducted by the Cosmetics Packaging Group found that 62% of consumers prefer environmentally friendly packaging, underscoring the importance of materials like pullulan in this sector.

Pullulan’s versatility in being molded into various forms, such as pouches, sachets, and coatings, significantly broadens its application scope. Its adaptability to different packaging scenarios, from single-use condiment sachets to multi-layered bulk storage pouches, demonstrates its potential to meet diverse industry needs. With its superior barrier properties, biodegradability, and non-toxic nature, pullulan stands out as a highly effective and sustainable packaging material across food, pharmaceutical, and cosmetic industries.

Moreover, pullulan can be combined with other biodegradable materials to enhance its properties. For example, it can be blended with other polysaccharides or biopolymers to improve its mechanical strength and barrier properties. This customization capability makes pullulan a highly versatile and valuable material for developing innovative packaging solutions.

Combining pullulan with other biodegradable materials allows for the creation of hybrid films and composites that possess enhanced characteristics suited for specific applications. For instance, blending pullulan with chitosan, another natural polysaccharide, can significantly improve the mechanical strength of the resulting material. Chitosan, derived from the shells of crustaceans, is known for its excellent film-forming ability and antimicrobial properties. When combined with pullulan, it can produce a packaging material that is not only strong but also capable of extending the shelf life of perishable foods by inhibiting microbial growth. Research published in the International Journal of Biological Macromolecules showed that pullulan-chitosan films had a tensile strength of 45 MPa, compared to 30 MPa for pure pullulan films, indicating a 50% improvement in strength.

In another example, pullulan can be blended with polylactic acid (PLA), a widely used biopolymer derived from corn starch. PLA is known for its high strength and biodegradability but has limitations in terms of flexibility and barrier properties. By combining pullulan with PLA, the resulting composite material can exhibit improved flexibility and enhanced barrier properties against moisture and gases. This makes it suitable for applications such as food packaging, where both durability and preservation are crucial. A study in the Journal of Applied Polymer Science demonstrated that pullulan-PLA films exhibited a 20% improvement in moisture barrier properties compared to pure PLA films, highlighting the potential of this blend for packaging applications.

The ability to customize pullulan by blending it with other biopolymers opens up numerous possibilities for innovative packaging solutions. For example, pullulan can be combined with starch to create biodegradable packaging films that are cost-effective and suitable for high-volume applications. Starch, being abundant and inexpensive, reduces the overall cost of the material, while pullulan enhances the film’s barrier and mechanical properties. This combination is particularly useful for packaging dry goods such as cereals and snacks. The global market for biodegradable packaging is expected to reach $21.6 billion by 2025, driven by consumer demand for sustainable packaging solutions, and pullulan-based composites can play a significant role in meeting this demand.

Furthermore, pullulan’s ability to be customized extends beyond blending with other polysaccharides. It can also be combined with natural additives and fillers to enhance specific properties. For example, incorporating essential oils like oregano or thyme into pullulan films can impart antimicrobial properties, making the packaging material suitable for preserving fresh produce and meat products. A study published in Food Packaging and Shelf Life found that pullulan films infused with oregano oil showed a 75% reduction in bacterial growth on packaged meat products compared to control samples.

The customization capability of pullulan through blending with other biodegradable materials significantly enhances its properties and expands its application potential. By improving mechanical strength, flexibility, and barrier properties, these hybrid materials offer innovative solutions for food, pharmaceutical, and cosmetic packaging. The ability to tailor pullulan composites to meet specific requirements makes it a highly versatile and valuable material in the development of sustainable and high-performance packaging solutions.

Economic and Market Potential

The economic potential of pullulan-based packaging is significant. As consumer awareness of environmental issues grows, the demand for sustainable packaging solutions is increasing. Companies that adopt pullulan-based packaging can not only reduce their environmental impact but also appeal to eco-conscious consumers, thereby gaining a competitive advantage in the market.

The economic potential of pullulan-based packaging is significant. As consumer awareness of environmental issues grows, the demand for sustainable packaging solutions is increasing. Companies that adopt pullulan-based packaging can not only reduce their environmental impact but also appeal to eco-conscious consumers, thereby gaining a competitive advantage in the market.

A survey by Nielsen found that 73% of global consumers are willing to change their consumption habits to reduce their environmental impact, and 81% of respondents felt strongly that companies should help improve the environment. This shift in consumer preference creates a lucrative opportunity for businesses that adopt eco-friendly packaging solutions like pullulan. For example, a company that switches to pullulan-based packaging can prominently market this change, potentially attracting a larger customer base and increasing brand loyalty among environmentally conscious consumers.

Furthermore, advances in production technology are making the manufacturing of pullulan more cost-effective. For instance, improvements in the fermentation process and the development of more efficient microbial strains have increased the yield and reduced the cost of pullulan production. According to a report by Grand View Research, the global market for bioplastics is expected to reach $68.5 billion by 2024, driven in part by technological advancements that lower production costs. As production scales up, the cost of pullulan-based packaging is expected to become more competitive with traditional plastic packaging, making it a viable alternative for a broader range of applications.

For example, companies like Japan’s Hayashibara Co., a leading producer of pullulan, have invested in research and development to optimize the fermentation process, resulting in a more efficient and cost-effective production method. As a result, the cost of pullulan has decreased over the years, making it more accessible to various industries.

Additionally, economies of scale play a crucial role in reducing costs. As more companies adopt pullulan-based packaging, the increased demand will drive further investment in production facilities, leading to lower unit costs. This trend is similar to what has been observed with other bioplastics, where increased production capacity has led to significant cost reductions. A study by the European Bioplastics Association found that the price of some bioplastics has decreased by up to 50% over the past decade due to economies of scale and technological advancements.

The economic potential of pullulan-based packaging is substantial. By meeting the growing consumer demand for sustainable products, companies can gain a competitive edge while contributing to environmental conservation. Advances in production technology and economies of scale are making pullulan-based packaging increasingly cost-effective, positioning it as a viable and attractive alternative to traditional plastic packaging. As the market for sustainable packaging continues to expand, pullulan-based solutions are poised to play a significant role in the future of the packaging industry.

Conclusion

Pullulan powder presents a compelling solution to the environmental challenges posed by traditional plastic packaging. Its biodegradability, non-toxicity, and film-forming capabilities make it an ideal material for eco-friendly packaging applications across various industries, including food, pharmaceuticals, and cosmetics. As the world continues to prioritize sustainability, pullulan-based packaging offers a promising path forward, combining environmental benefits with practical functionality. Embracing pullulan as a packaging material can significantly reduce the ecological footprint of packaging and contribute to a more sustainable future.