The Role of Pullulan in Vaccine Stability and Delivery

In the rapidly evolving field of biotechnology, the quest for improved vaccine formulations and delivery methods is ongoing. Among the myriad of materials being explored, pullulan—a naturally occurring polysaccharide produced by the fungus Aureobasidium pullulans—has garnered significant attention. Renowned for its unique properties, pullulan offers promising applications in enhancing vaccine stability and delivery. This article delves into the critical role of pullulan in vaccine technology and highlights its advantages in the pharmaceutical industry.

Understanding Pullulan

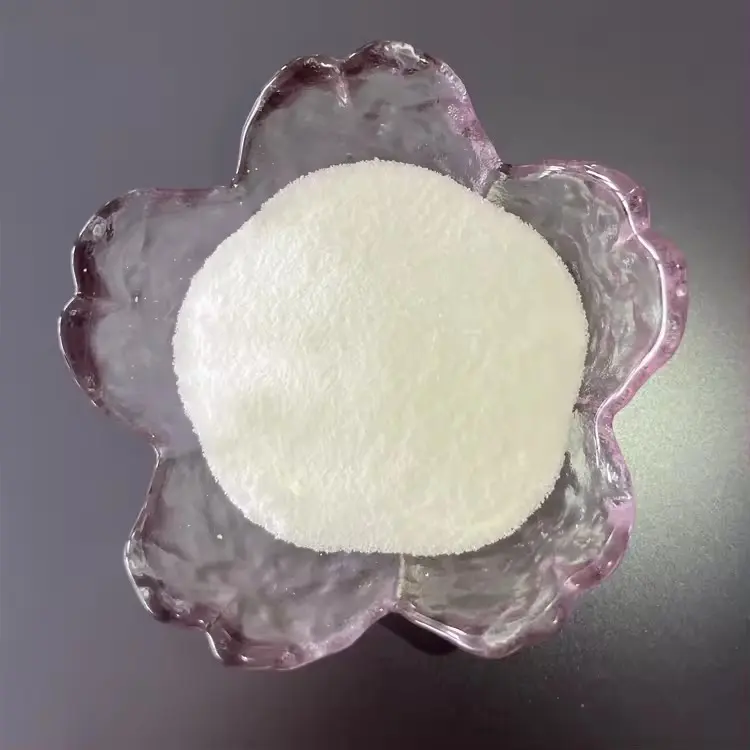

Pullulan is a water-soluble polysaccharide consisting of maltotriose units, which are linked by α-(1→4) and α-(1→6) glycosidic bonds. Its unique structure imparts several desirable properties, such as:

Biocompatibility and Biodegradability: Pullulan is non-toxic and environmentally friendly, making it ideal for medical and pharmaceutical applications.

Film-Forming Ability: It can form strong, elastic films, which are beneficial for creating protective coatings.

Oxygen Barrier: Pullulan films exhibit excellent oxygen barrier properties, crucial for preserving the integrity of sensitive biological materials.

Pullulan in Vaccine Stability

Vaccine stability is paramount to ensuring the efficacy and safety of immunizations. Vaccines, especially those containing live or attenuated viruses, are highly susceptible to environmental conditions such as temperature and humidity. Pullulan offers several mechanisms to enhance vaccine stability:

Protective Coatings: Pullulan can form a protective barrier around vaccine particles, shielding them from environmental stressors. This is particularly useful in oral vaccines, where the harsh gastric environment can degrade the vaccine components.

Lyophilization Aid: Lyophilization, or freeze-drying, is a common method to stabilize vaccines. Pullulan serves as an excellent lyoprotectant, maintaining the structural integrity of the vaccine during the freeze-drying process and subsequent storage.

Moisture Absorption: Pullulan's hygroscopic nature helps in maintaining the moisture balance, preventing degradation caused by humidity.

Pullulan in Vaccine Delivery

Efficient delivery of vaccines is as crucial as their stability. The unique properties of pullulan make it a versatile tool in enhancing vaccine delivery systems:

Encapsulation: Pullulan can encapsulate vaccine antigens, protecting them from degradation while facilitating controlled release. This encapsulation ensures that the vaccine is delivered effectively to the target site, enhancing the immune response.

Oral Vaccines: The development of oral vaccines has been a significant challenge due to the digestive system's harsh conditions. Pullulan's film-forming ability can be utilized to create enteric coatings that protect the vaccine until it reaches the intestines, where it can be absorbed.

Mucosal Delivery: Pullulan-based films and gels can be used for mucosal delivery of vaccines, targeting sites such as the nasal or buccal cavities. This method of delivery can induce both systemic and mucosal immunity, providing comprehensive protection against pathogens.

Case Studies and Applications

1. Influenza Vaccines

Research has demonstrated that pullulan can be used to stabilize influenza vaccines. In one study, pullulan was employed as a stabilizing agent during the freeze-drying process, resulting in a vaccine formulation that retained its potency after extended storage at varying temperatures. The pullulan-stabilized vaccine exhibited enhanced immunogenicity, highlighting its potential in improving vaccine efficacy.

2. Hepatitis B Vaccines

Pullulan has also shown promise in the delivery of hepatitis B vaccines. By encapsulating the hepatitis B surface antigen (HBsAg) in pullulan-based nanoparticles, researchers achieved a sustained release of the antigen, leading to prolonged immune responses. This method not only improved the stability of the antigen but also reduced the number of doses required, simplifying vaccination schedules.

3. COVID-19 Vaccines

The COVID-19 pandemic underscored the need for stable and easily deployable vaccines. Pullulan-based formulations have been explored to enhance the stability and delivery of mRNA vaccines. Pullulan's ability to form protective films and its compatibility with various adjuvants make it a suitable candidate for next-generation vaccine platforms.

Advantages of Pullulan in Vaccine Formulations

Safety: As a natural polysaccharide, pullulan is biocompatible and has a well-established safety profile. It is non-toxic and does not elicit significant immune responses on its own, making it an ideal excipient in vaccines.

Versatility: Pullulan's ability to form films, gels, and nanoparticles allows for diverse applications in vaccine formulations. It can be tailored to suit various delivery methods, including oral, nasal, and injectable vaccines.

Cost-Effectiveness: Pullulan is relatively easy to produce and purify, offering a cost-effective solution for large-scale vaccine production. Its stability-enhancing properties can reduce the need for cold chain logistics, further lowering costs.

Enhanced Immune Response: By protecting the antigen and ensuring its controlled release, pullulan can enhance the immunogenicity of vaccines, leading to stronger and longer-lasting immune responses.

Exploring the Science Behind Pullulan's Benefits

Molecular Structure and Properties

To fully appreciate the benefits of pullulan in vaccine stability and delivery, it is essential to delve deeper into its molecular structure. Pullulan is a linear polysaccharide composed of repeating units of maltotriose, which consists of three glucose molecules linked by α-(1→4) glycosidic bonds. These maltotriose units are connected by α-(1→6) glycosidic bonds, giving pullulan its unique structure.

This structure imparts several significant properties to pullulan:

High Solubility in Water: Pullulan dissolves easily in water, forming clear solutions. This high solubility is advantageous in pharmaceutical formulations where uniform distribution of ingredients is required.

Film-Forming Ability: The ability to form strong, flexible films is due to the intermolecular hydrogen bonds that stabilize the structure. These films can be used to encapsulate vaccines, protecting them from environmental factors.

Non-Reducing Sugar: Unlike other polysaccharides, pullulan is a non-reducing sugar, which means it does not participate in Maillard reactions. This property is crucial for maintaining the stability of sensitive pharmaceutical compounds that can degrade in the presence of reducing sugars.

The Role of Pullulan in Enhancing Vaccine Efficacy

Adjuvant Potential

Adjuvants are substances that enhance the body's immune response to an antigen. While pullulan itself is not traditionally considered an adjuvant, its ability to stabilize and deliver antigens effectively can enhance vaccine efficacy indirectly. By protecting the antigen from degradation and ensuring its proper presentation to the immune system, pullulan can contribute to a more robust and sustained immune response.

Sustained Release Systems

One of the significant challenges in vaccine delivery is achieving a sustained release of the antigen to prolong immune stimulation. Pullulan-based systems can encapsulate antigens and release them gradually over time. This sustained release mimics natural infection, where the immune system is exposed to the pathogen for an extended period, leading to better memory cell formation and long-lasting immunity.

Innovative Applications of Pullulan in Vaccine Formulations

Nanoparticle-Based Vaccines

Nanoparticle technology is revolutionizing vaccine delivery by allowing for precise control over the size, shape, and surface characteristics of the vaccine particles. Pullulan can be used to create nanoparticles that encapsulate the antigen, protecting it from degradation and enhancing its uptake by immune cells.

These pullulan-based nanoparticles can be engineered to have surface modifications that target specific cells or tissues, improving the efficiency of antigen delivery. For instance, surface modifications with ligands that target dendritic cells can enhance the uptake and presentation of the antigen, leading to a stronger immune response.

Microneedle Patches

Microneedle patches are an emerging technology for vaccine delivery that offers a painless and straightforward alternative to traditional injections. These patches consist of tiny needles that painlessly penetrate the outer layer of the skin, delivering the vaccine directly to the immune-rich dermal layer.

Pullulan can be used to fabricate microneedles due to its excellent film-forming properties and biocompatibility. Pullulan-based microneedles can encapsulate the vaccine and deliver it in a controlled manner, ensuring the antigen's stability and efficacy.

Oral Vaccine Formulations

Oral vaccines offer several advantages, including ease of administration and the potential to induce mucosal immunity. However, the harsh conditions of the gastrointestinal tract pose a significant challenge to the stability of orally administered vaccines.

Pullulan's film-forming ability and resistance to digestive enzymes make it an ideal candidate for developing enteric coatings for oral vaccines. These coatings protect the vaccine as it passes through the stomach, releasing it only when it reaches the more neutral pH environment of the intestines.

Pullulan in the Global Vaccine Market

Addressing Cold Chain Logistics

One of the significant challenges in vaccine distribution, especially in low-resource settings, is the reliance on cold chain logistics. Many vaccines require constant refrigeration from the point of manufacture to administration, which can be difficult to maintain in regions with limited infrastructure.

Pullulan's stabilizing properties can help reduce the dependency on cold chain logistics. By enhancing the stability of vaccines, pullulan allows for storage and transportation at ambient temperatures, making vaccines more accessible to remote and underserved populations.

Case Studies in Developing Countries

In developing countries, the need for stable and easily deployable vaccines is paramount. Pullulan-based formulations have the potential to revolutionize vaccine delivery in these regions. For instance, pullulan-stabilized oral vaccines could significantly improve immunization rates by simplifying the logistics of vaccine storage and distribution.

Regulatory and Safety Considerations

Regulatory Approvals

For any new excipient or delivery system to be used in vaccines, it must undergo rigorous testing and regulatory approval processes. Pullulan has a well-established safety profile and is recognized as Generally Recognized As Safe (GRAS) by regulatory agencies like the FDA. Its biocompatibility and non-toxicity make it a promising candidate for inclusion in vaccine formulations.

Quality Control and Manufacturing Standards

Ensuring the quality and consistency of pullulan is crucial for its use in pharmaceuticals. At Shandong Mimei Biotechnology Co., Ltd., we adhere to stringent quality control measures to guarantee the purity and performance of our pullulan products. Our manufacturing facilities comply with ISO22000, ISO14001, and ISO45001 standards, and we have obtained organic, kosher, and halal certifications, ensuring our products meet the highest international standards.

The Future of Pullulan in Vaccine Technology

Research and Development

Ongoing research is essential to unlock the full potential of pullulan in vaccine technology. Collaborative efforts between academic institutions, industry, and regulatory bodies can drive innovation and bring new pullulan-based vaccine formulations to market. Areas of research include:

Improving Encapsulation Techniques: Developing advanced methods for encapsulating antigens within pullulan matrices to enhance stability and release profiles.

Targeted Delivery Systems: Engineering pullulan nanoparticles with surface modifications that target specific immune cells or tissues.

Combination Therapies: Exploring the use of pullulan in combination with other adjuvants or delivery systems to enhance vaccine efficacy.

Conclusion

The role of pullulan in vaccine stability and delivery represents a significant advancement in the field of biotechnology. Its unique properties make it an invaluable tool in developing more stable, effective, and accessible vaccines. As the global demand for vaccines continues to rise, the integration of pullulan into vaccine formulations could revolutionize immunization strategies and improve public health outcomes.

Pullulan's unique properties make it an invaluable tool in the quest for more stable and effective vaccines. Its ability to protect and deliver antigens in a controlled manner can significantly enhance vaccine efficacy, reduce the need for cold chain logistics, and improve accessibility in low-resource settings.

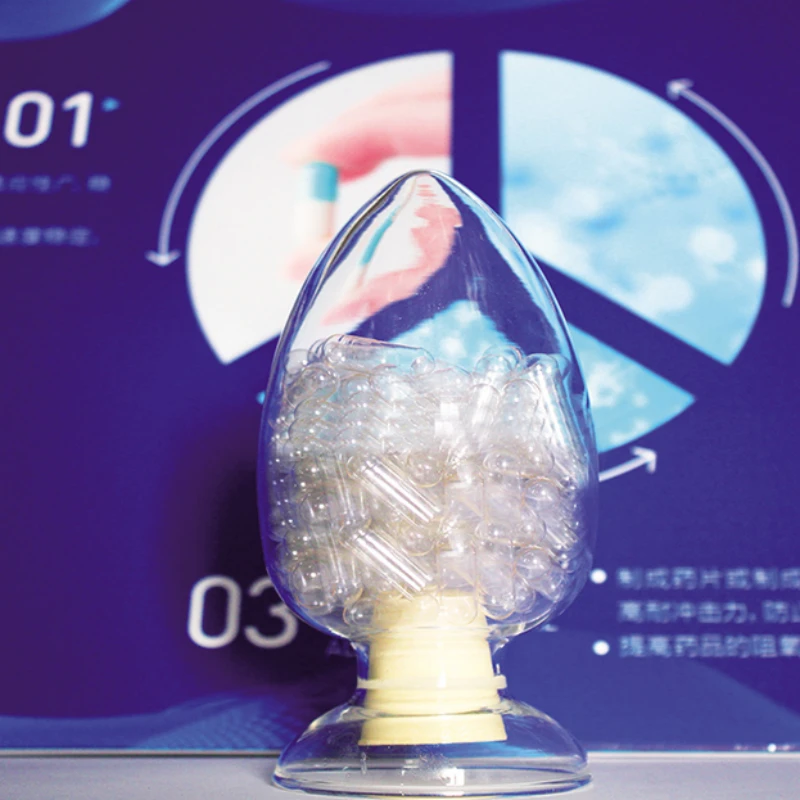

Shandong Mimei Biotechnology Co., Ltd.: Leading the Way in Pullulan Innovation

At Shandong Mimei Biotechnology Co., Ltd., we pride ourselves on being at the forefront of pullulan production and innovation. Established in 2019, we have rapidly become a leading manufacturer and supplier of pullulan and related bio-polysaccharide products in China. Our state-of-the-art facility spans over 100,000 square meters, with an impressive annual output of 3,000 tons of pullulan, 10 billion pullulan hollow capsules, and 80 million pullulan biopolysaccharide films.

Our commitment to quality is demonstrated through our extensive certifications, including ISO22000, ISO14001, and ISO45001 quality system certifications, as well as organic, kosher, and halal certifications. These accolades underscore our dedication to producing high-quality, safe, and reliable pullulan products.

With strong technical capabilities and extensive manufacturing experience, Shandong Mimei Biotechnology Co., Ltd. is poised to support the pharmaceutical industry's evolving needs. Our pullulan products are designed to enhance vaccine stability and delivery, contributing to the development of more effective and accessible vaccines.

Explore the potential of pullulan with Shandong Mimei Biotechnology Co., Ltd. and join us in advancing the future of vaccine technology. For more information, please visit our website or contact our sales team to learn how our products can meet your specific needs.