Pullulan powder, a polysaccharide produced by the fungus Aureobasidium pullulans, has gained significant attention in various industries due to its unique properties. One of the most promising and lesser-known applications of pullulan is its use in antimicrobial coatings. These coatings can be instrumental in enhancing the safety and longevity of products in sectors ranging from food packaging to medical devices. In this article, we explore the antimicrobial properties of pullulan powder coatings and their potential benefits.

The Science Behind Pullulan's Antimicrobial Action

Pullulan's antimicrobial properties are primarily attributed to its exceptional film-forming capabilities, which allow it to incorporate and stabilize a variety of antimicrobial agents. These agents can be natural, such as essential oils and plant extracts, or synthetic, including silver nanoparticles and various chemical compounds. When pullulan is used as a coating material, it effectively encapsulates these antimicrobial substances within its matrix. This encapsulation process not only stabilizes the antimicrobial agents, preventing their rapid degradation, but also facilitates a controlled and sustained release over time.

The controlled release mechanism of pullulan-based films is particularly beneficial in applications where long-term protection against microbial contamination is required. For instance, in the food industry, pullulan coatings can be applied to fresh produce, meats, and dairy products to inhibit the growth of harmful bacteria, fungi, and yeasts. The sustained release of antimicrobial agents from pullulan films ensures that the protective effect lasts throughout the product's shelf life, significantly reducing the risk of spoilage and extending freshness.

Moreover, the versatility of pullulan allows it to be combined with different antimicrobial agents tailored to specific needs. For example, essential oils like thyme or oregano oil, known for their natural antimicrobial properties, can be incorporated into pullulan films to create a natural and effective barrier against pathogens. Similarly, the inclusion of silver nanoparticles, which possess potent antibacterial properties, can enhance the effectiveness of pullulan coatings in medical and pharmaceutical applications, such as wound dressings and surgical masks.

Research has demonstrated the efficacy of pullulan films in various settings. A study published in the Journal of Food Science showed that pullulan films infused with essential oils exhibited significant antimicrobial activity against common foodborne pathogens like Escherichia coli and Staphylococcus aureus. This highlights the potential of pullulan as a key material in developing safer and more sustainable packaging solutions. Another study exploring the use of pullulan coatings in medical devices found that films containing silver nanoparticles effectively inhibited bacterial growth, suggesting their utility in preventing infections associated with medical implants and devices.

Pullulan's ability to form films that can incorporate and stabilize antimicrobial agents, coupled with its controlled release properties, makes it an invaluable material for protecting against microbial contamination across various industries. Its versatility and effectiveness pave the way for innovative applications in food safety, healthcare, and beyond.

Applications in Food Packaging

One of the most practical applications of pullulan powder coatings is in the food packaging industry, where ensuring food safety and extending shelf life are critical. Microbial contamination in food can lead to spoilage, foodborne illnesses, and significant economic losses. Pullulan coatings offer an effective barrier against microbial invasion, thereby extending the shelf life of perishable products and enhancing food safety.

Pullulan films, when used in food packaging, provide several key benefits. Firstly, their antimicrobial properties inhibit the growth of bacteria, fungi, and yeasts that cause spoilage. For example, pullulan coatings infused with essential oils like thyme or oregano can effectively prevent the growth of common foodborne pathogens such as Escherichia coli and Staphylococcus aureus. This antimicrobial action is crucial for maintaining the freshness and safety of foods during storage and transportation.

Moreover, pullulan films are biodegradable, edible, and non-toxic, making them an ideal choice for applications involving direct food contact. Unlike traditional plastic films, which contribute to environmental pollution and are not suitable for consumption, pullulan films decompose naturally and can be safely ingested if they come into contact with food. This characteristic is particularly advantageous for packaging fresh produce, meats, and dairy products, where food safety and environmental sustainability are paramount concerns.

The transparency of pullulan films is another significant advantage. It ensures that the visual appeal of the packaged food is maintained, which is important for consumer satisfaction and marketability. Fruits and vegetables coated with pullulan films retain their natural appearance, making them more attractive to consumers. For instance, strawberries coated with pullulan not only stay fresh longer but also maintain their vibrant color and texture, which are essential qualities for market acceptance.

In addition to fruits and vegetables, pullulan coatings can be applied to a wide range of perishable foods. Meat products, for example, benefit from pullulan's ability to form a protective barrier that reduces moisture loss and inhibits the growth of spoilage microorganisms. Dairy products like cheese and yogurt can also be packaged in pullulan films to extend their shelf life without compromising flavor or quality.

The application process for pullulan coatings is relatively straightforward and can be integrated into existing packaging lines. Foods can be dipped or sprayed with pullulan solutions, followed by a drying step to form a uniform, protective film. This ease of application makes pullulan a practical solution for food manufacturers looking to enhance the safety and longevity of their products.

Beyond extending shelf life and ensuring food safety, pullulan coatings align with the growing consumer demand for sustainable and eco-friendly packaging solutions. As more consumers become aware of the environmental impact of plastic waste, the demand for biodegradable alternatives like pullulan is increasing. By adopting pullulan coatings, food manufacturers can appeal to eco-conscious consumers and differentiate their products in a competitive market.

Pullulan powder coatings represent a versatile and effective solution for the food packaging industry. Their antimicrobial properties, biodegradability, edibility, and transparency make them ideal for preserving the freshness and safety of perishable foods. As consumer preferences shift towards sustainable packaging options, pullulan offers a promising alternative that meets both food safety requirements and environmental goals.

Medical and Pharmaceutical Applications

In the medical and pharmaceutical sectors, pullulan powder coatings offer significant advantages in ensuring sterility and preventing infections. Medical devices, such as catheters, implants, and surgical instruments, are particularly susceptible to microbial colonization, which can lead to severe infections and complications. Coating these devices with pullulan infused with antimicrobial agents can provide a robust defense against pathogenic microorganisms, significantly reducing the risk of infection.

The application of pullulan coatings to medical devices can be achieved through various methods, including dipping, spraying, or electrospinning. These coatings can be infused with a range of antimicrobial agents, such as silver nanoparticles, antibiotics, or natural antimicrobial substances like essential oils. The antimicrobial agents embedded within the pullulan matrix are gradually released over time, providing sustained protection against microbial colonization and biofilm formation. For example, a study published in the Journal of Biomedical Materials Research demonstrated that catheters coated with pullulan containing silver nanoparticles exhibited strong antibacterial activity against Staphylococcus aureus and Escherichia coli, two common pathogens responsible for device-related infections.

Moreover, pullulan's biocompatibility and biodegradability make it an excellent material for use in wound dressings and drug delivery systems. Wound dressings incorporating pullulan can protect the wound site from infections while promoting healing. Pullulan-based hydrogels, for instance, can be loaded with antimicrobial agents and applied to wounds. These hydrogels create a moist environment conducive to healing while continuously releasing antimicrobial substances to control bacterial growth. Studies have demonstrated that pullulan-based hydrogels loaded with agents such as chlorhexidine or silver ions can effectively reduce bacterial load in wounds and support tissue regeneration.

In a clinical context, pullulan-based wound dressings offer several advantages. They are non-toxic, non-irritating, and can be easily removed without causing trauma to the healing tissue. Their biodegradability ensures that any residue left in the wound is safely absorbed by the body, eliminating the need for dressing changes and reducing patient discomfort. Additionally, the transparent nature of pullulan films allows for easy monitoring of the wound healing process without removing the dressing, thus minimizing disruption to the wound site.

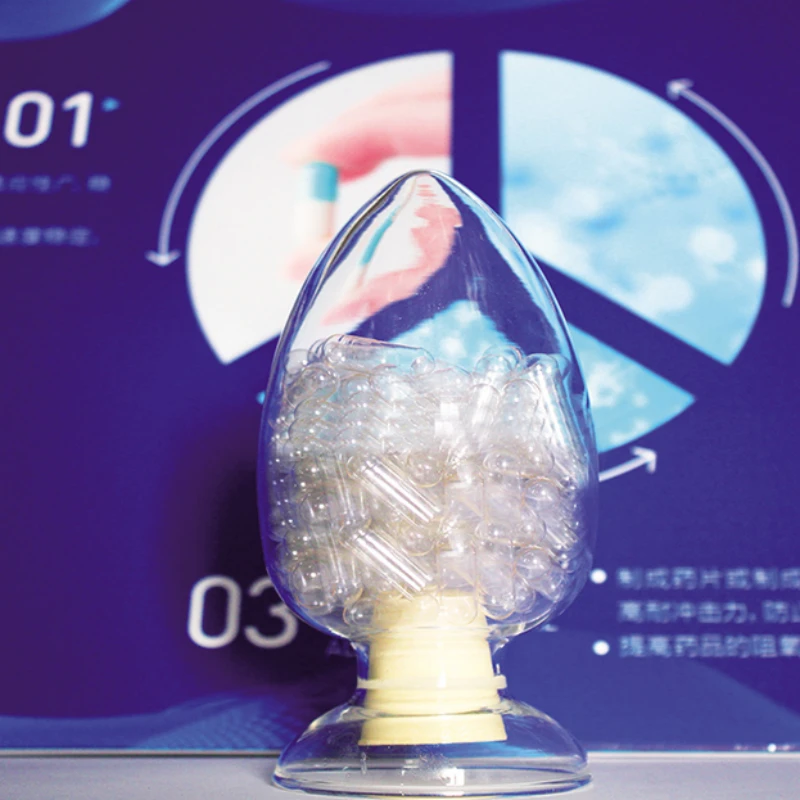

In drug delivery systems, pullulan's unique properties enable the development of advanced formulations for controlled and targeted drug release. Pullulan can be used to create nanoparticles, micelles, or hydrogels that encapsulate therapeutic agents. These delivery systems can enhance the bioavailability and efficacy of drugs while reducing side effects. For example, pullulan nanoparticles loaded with anticancer drugs like doxorubicin have shown promise in targeting tumor cells more effectively, reducing the required dosage and minimizing systemic toxicity.

Furthermore, pullulan can be functionalized with specific ligands or peptides to target particular cells or tissues, improving the precision of drug delivery. This capability is particularly valuable in the treatment of diseases such as cancer, where targeted therapy can significantly improve patient outcomes. For instance, a study published in the journal Biomaterials reported that pullulan nanoparticles functionalized with folic acid effectively targeted cancer cells expressing folate receptors, enhancing the delivery and efficacy of the encapsulated chemotherapeutic agents.

Pullulan-based drug delivery systems are also being explored for their potential in oral, nasal, and transdermal drug administration. The versatility of pullulan allows for the formulation of tablets, films, or patches that can deliver drugs through various routes, catering to different therapeutic needs. In oral drug delivery, pullulan films can be designed to dissolve rapidly in the mouth, providing a convenient and effective method for administering medications to patients with swallowing difficulties.

Pullulan powder coatings offer significant advantages in the medical and pharmaceutical sectors. Their antimicrobial properties, biocompatibility, and biodegradability make them ideal for ensuring sterility and preventing infections in medical devices and wound dressings. Additionally, pullulan's versatility in drug delivery systems enables the development of advanced formulations for controlled and targeted drug release, enhancing therapeutic efficacy and patient outcomes. As research and development in this field continue to advance, pullulan is poised to play a pivotal role in improving healthcare solutions and patient care.

Environmental and Economic Benefits

The environmental impact of antimicrobial coatings is a growing concern, especially with the widespread use of synthetic materials and chemicals. These conventional coatings often contain persistent chemicals that do not break down easily in the environment, leading to long-term pollution and adverse ecological effects. Pullulan, however, stands out as an environmentally friendly alternative due to its natural origin and biodegradability. Derived from the fermentation of starch by the fungus Aureobasidium pullulans, pullulan is a polysaccharide that decomposes naturally, significantly minimizing its ecological footprint. This biodegradability ensures that pullulan-based coatings do not accumulate in the environment, reducing the risk of long-term pollution and associated environmental damage.

In addition to its environmental benefits, pullulan's natural origin means it does not introduce harmful chemicals into ecosystems. As it breaks down, pullulan does not release toxic byproducts into the soil or water, ensuring that its use is safe for the environment. This is in stark contrast to many synthetic antimicrobial coatings that can leach harmful substances as they degrade. The eco-friendly nature of pullulan makes it particularly suitable for applications where environmental safety is a priority, such as in food packaging, medical devices, and personal care products.

From an economic perspective, the use of pullulan coatings can lead to substantial cost savings, particularly in industries where product spoilage and shelf life are critical concerns. In the food industry, for example, microbial contamination is a major cause of spoilage, leading to significant economic losses. Pullulan coatings can act as effective barriers against microbial invasion, thereby extending the shelf life of perishable goods such as fruits, vegetables, and meats. This extension of shelf life not only helps in reducing food waste but also in decreasing the financial burden associated with spoilage. A study published in the Journal of Food Science demonstrated that pullulan films containing essential oils exhibited significant antimicrobial activity against common foodborne pathogens like Escherichia coli and Staphylococcus aureus, effectively enhancing the safety and longevity of food products.

Moreover, pullulan's versatility allows manufacturers to tailor coatings to meet specific needs, optimizing performance and cost-effectiveness. For instance, pullulan can be blended with other biopolymers or antimicrobial agents to enhance its mechanical strength and barrier properties, creating customized solutions for various applications. This adaptability ensures that pullulan coatings can be designed to deliver optimal performance under specific conditions, whether it is in the packaging of delicate fresh produce or in the protection of medical devices. By customizing pullulan formulations, manufacturers can achieve the desired balance between efficacy and cost, ensuring that the coatings provide maximum benefit at a reasonable expense.

In the medical field, the cost savings from using pullulan coatings can be significant as well. Medical devices such as catheters, implants, and surgical instruments are prone to microbial colonization, leading to infections that can complicate treatments and increase healthcare costs. Coating these devices with pullulan infused with antimicrobial agents can reduce the incidence of infections, thereby lowering the associated medical expenses and improving patient outcomes. Pullulan-based hydrogels used in wound dressings have been shown to reduce bacterial load in wounds and promote healing, further exemplifying the cost-effective benefits of pullulan in medical applications.

The economic viability of pullulan is also enhanced by advances in production technology. As production methods become more efficient and scalable, the cost of manufacturing pullulan is expected to decrease, making it an increasingly competitive alternative to conventional synthetic coatings. This cost reduction can make pullulan-based coatings accessible to a broader range of applications and industries, further driving their adoption and contributing to overall cost savings.

Pullulan presents a compelling case as an environmentally friendly and economically viable antimicrobial coating. Its natural origin and biodegradability ensure minimal environmental impact, addressing growing concerns about the ecological footprint of synthetic materials. Economically, pullulan coatings offer significant cost savings by reducing product spoilage, extending shelf life, and lowering healthcare costs associated with infections. The versatility and adaptability of pullulan further enhance its appeal, allowing manufacturers to tailor coatings to specific needs and optimize performance. As production technologies advance, pullulan's role as a sustainable and cost-effective solution is poised to expand, benefiting various industries and contributing to a more sustainable future.

Future Prospects

The potential of pullulan powder coatings is vast and continues to be explored by researchers and industry professionals. Advances in nanotechnology and materials science are likely to enhance the functionality of pullulan coatings further, making them even more effective and versatile. For instance, the development of pullulan-based nanocomposites with enhanced mechanical and antimicrobial properties could revolutionize various applications.

Nanotechnology, a rapidly evolving field, offers exciting possibilities for enhancing pullulan coatings. By incorporating nanoparticles into pullulan films, researchers can significantly improve their mechanical strength, flexibility, and antimicrobial efficacy. For example, silver nanoparticles are well-known for their potent antimicrobial properties. When embedded in pullulan films, they can provide a powerful defense against a wide range of pathogens, including bacteria, fungi, and viruses. Studies have demonstrated that pullulan-silver nanocomposite films exhibit superior antimicrobial activity compared to conventional pullulan films, making them ideal for applications in food packaging, medical devices, and healthcare products.

In food packaging, pullulan-based nanocomposites can extend the shelf life of perishable goods even further. The incorporation of nanoparticles can enhance the barrier properties of pullulan films, making them more effective at preventing the transmission of oxygen, moisture, and other contaminants that contribute to food spoilage. This improved barrier function can help maintain the freshness and quality of packaged food items for longer periods. For instance, a study published in the Journal of Agricultural and Food Chemistry found that pullulan films containing zinc oxide nanoparticles effectively inhibited the growth of Escherichia coli and Listeria monocytogenes, two common foodborne pathogens. This suggests that pullulan-based nanocomposites could play a critical role in enhancing food safety and reducing waste.

In the medical and pharmaceutical sectors, pullulan nanocomposites hold great promise for improving the performance and safety of various products. The enhanced mechanical properties of these nanocomposites can make medical coatings more durable and resistant to wear and tear, ensuring long-lasting protection against microbial contamination. Additionally, the controlled release of antimicrobial agents from pullulan-based nanocomposites can provide sustained protection, reducing the risk of infections associated with medical devices such as catheters, implants, and wound dressings. A study published in the journal Biomacromolecules demonstrated that pullulan films incorporating titanium dioxide nanoparticles exhibited excellent antimicrobial activity and biocompatibility, making them suitable for use in medical applications.

Moreover, the development of pullulan-based nanocomposites is not limited to antimicrobial applications. Researchers are exploring ways to enhance the functional properties of pullulan coatings for a variety of uses. For example, by incorporating bioactive nanoparticles, pullulan films can be engineered to deliver therapeutic agents directly to targeted sites in the body. This approach could revolutionize drug delivery systems, providing more efficient and effective treatments for various diseases. In one study, pullulan nanoparticles loaded with curcumin, a natural anti-inflammatory compound, were shown to enhance the bioavailability and therapeutic efficacy of curcumin, highlighting the potential of pullulan nanocomposites in advanced drug delivery.

In the realm of environmental sustainability, pullulan-based nanocomposites offer a promising solution to reduce the reliance on synthetic materials. As these nanocomposites are derived from natural sources and are biodegradable, they present a more eco-friendly alternative to conventional plastics and other non-biodegradable materials. This aligns with the growing demand for sustainable materials in various industries, including packaging, healthcare, and consumer goods. The ability to tailor the properties of pullulan nanocomposites to meet specific requirements further enhances their appeal, allowing manufacturers to develop customized solutions that address both performance and environmental concerns.

The economic potential of pullulan-based nanocomposites is also significant. As consumer awareness of environmental issues continues to grow, the demand for sustainable products is expected to increase. Companies that adopt pullulan nanocomposites can not only reduce their environmental impact but also appeal to eco-conscious consumers, gaining a competitive advantage in the market. Furthermore, advances in production technology are making the manufacturing of pullulan nanocomposites more cost-effective. As production scales up, the cost of these advanced materials is expected to become more competitive with traditional materials, broadening their application range and driving market adoption.

The potential of pullulan powder coatings is vast and multifaceted. Advances in nanotechnology and materials science are set to enhance the functionality of pullulan coatings, making them more effective and versatile for a wide range of applications. From improving food safety and extending shelf life to enhancing the performance of medical devices and promoting environmental sustainability, pullulan-based nanocomposites represent a promising frontier in materials science. As research and development continue, the future of pullulan coatings looks bright, offering innovative solutions to meet the evolving needs of various industries.

Conclusion

In conclusion, pullulan powder coatings offer a promising solution to the challenges of microbial contamination across multiple industries. Their unique combination of antimicrobial efficacy, biocompatibility, and environmental friendliness positions them as a valuable material for future innovations. As research and development continue, we can expect to see even broader applications and improved performance of pullulan-based antimicrobial coatings.

We are a leading manufacturer and wholesaler of pullulan powder, proudly offering high-quality products to customers worldwide. Our state-of-the-art production facilities and advanced technology ensure that our pullulan powder meets the highest industry standards, making it suitable for various applications, including food, pharmaceuticals, cosmetics, and more. We take pride in our commitment to quality, sustainability, and customer satisfaction.

Pullulan powder is renowned for its exceptional film-forming abilities, biodegradability, and non-toxic nature. It is an ideal ingredient for food packaging, providing an eco-friendly alternative to conventional plastics. In the pharmaceutical and cosmetic industries, pullulan is valued for its ability to enhance the stability and efficacy of products. Our pullulan powder is produced from renewable sources through a meticulous fermentation process, ensuring its purity and consistency.

We welcome inquiries and orders from clients across the globe. Our dedicated team is here to assist you with your specific needs, offering tailored solutions and reliable customer support. Whether you are looking to enhance your product formulations or seek sustainable alternatives, our pullulan powder is the perfect choice. Contact us to learn more about our offerings and how we can support your business.